Product features

1.The machine adopts high strength cast iron to eliminate internal stress,ensure high precision and strong bearing capacity.

2.Pneumatic clutch brake system and high-end solenoid valve ensure safety and stability.

3.The forced circulating lubricating oil device ensures the accuracy and stability of the high-speed operation of the machine,improves the service life of the machine,and is designed with advanced humanization.Electronic monitoring system can improve efficiency and quality.

Configuration

Standard accessory configuration | |

Human-Machine Interface | 1group |

servo motor | 1group |

Programmable logic controller(PLC) | 1group |

Electronic cam structure | 1group |

Inverter control | 1group |

Manual mold height adjustment | 1group |

Standard accessory configuration | |

Circulating lubrication oil supply system | 1group |

Maintenance tools and toolboxes | 1group |

Operating instructions and precision Inspection grade sheet | 1group |

Photoelectric protection configuration | 1group |

Oil pressure locking system | 1group |

Specification parameters

Project Model | SF-20E | ||

Nominal force | 20T | ||

Trip | 20 | 30 | 40 |

Number of trips | 60 ~ 150 | 60 ~ 150 | 60 ~ 120 |

Maximum mold height mm | 190 ~ 220 | 185 ~ 215 | 180 ~ 210 |

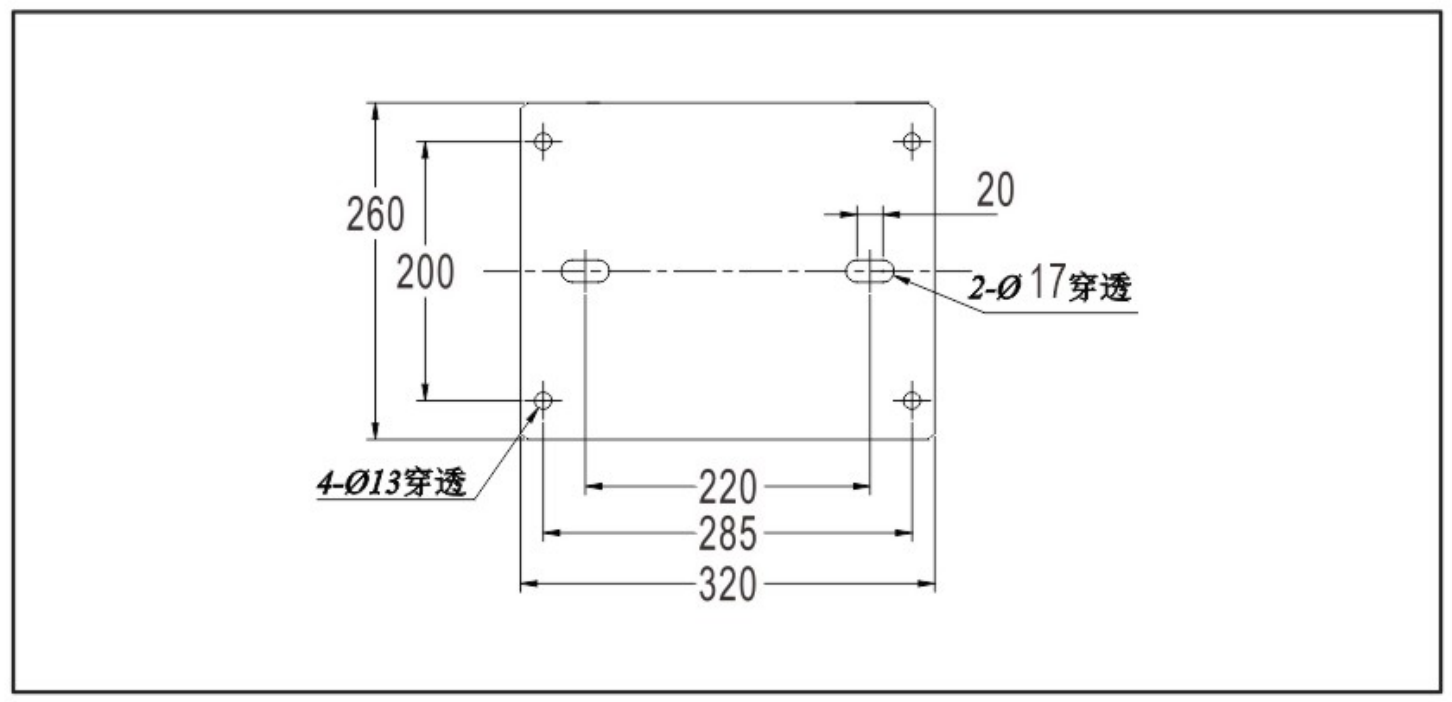

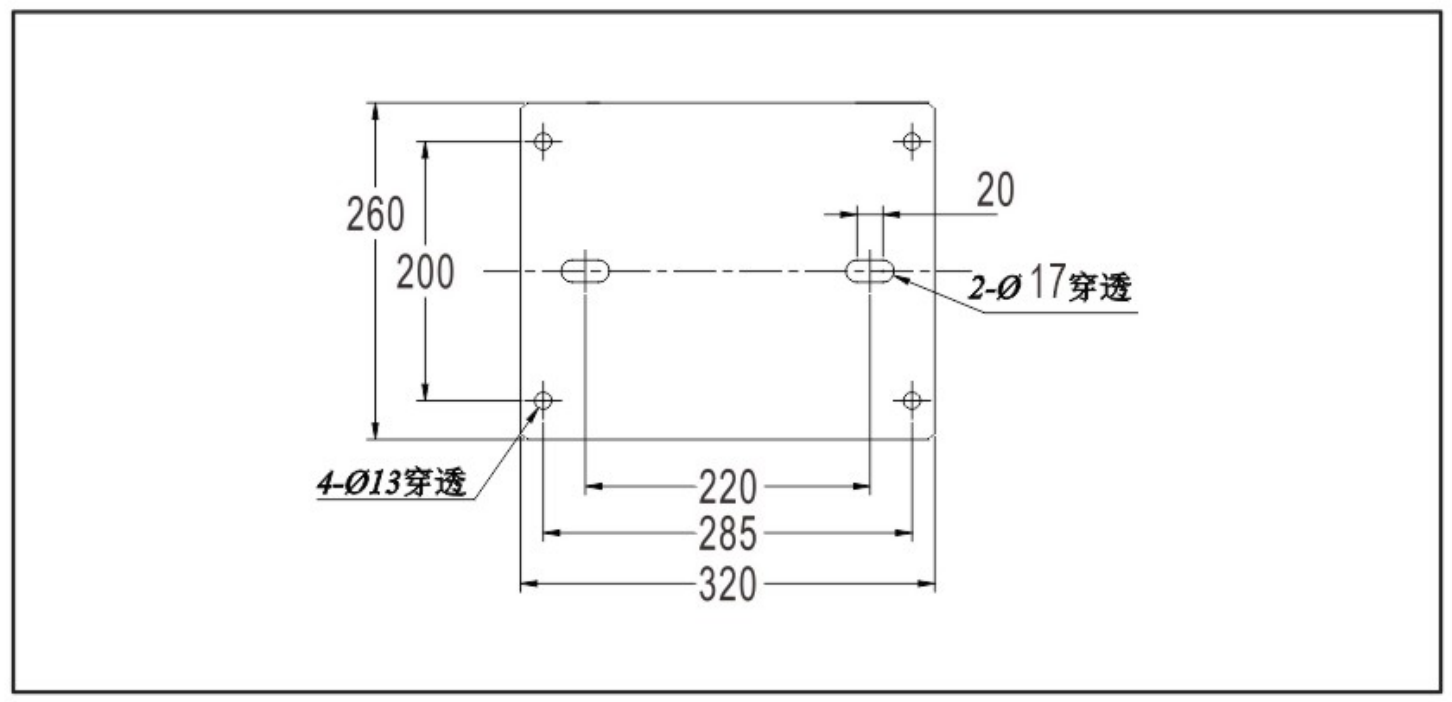

Size of upper table mm | 320 x 260 | ||

Installation hole distance of upper table mould | 210–230 | ||

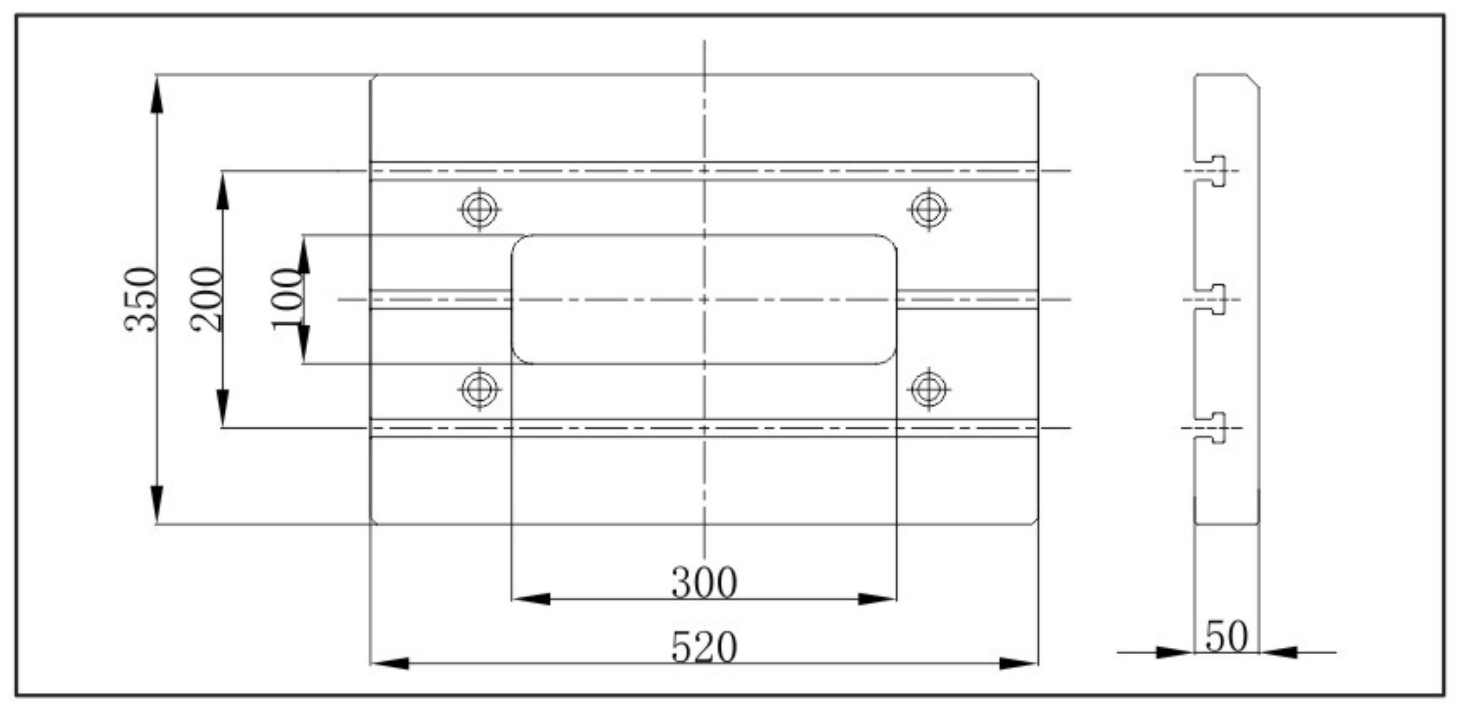

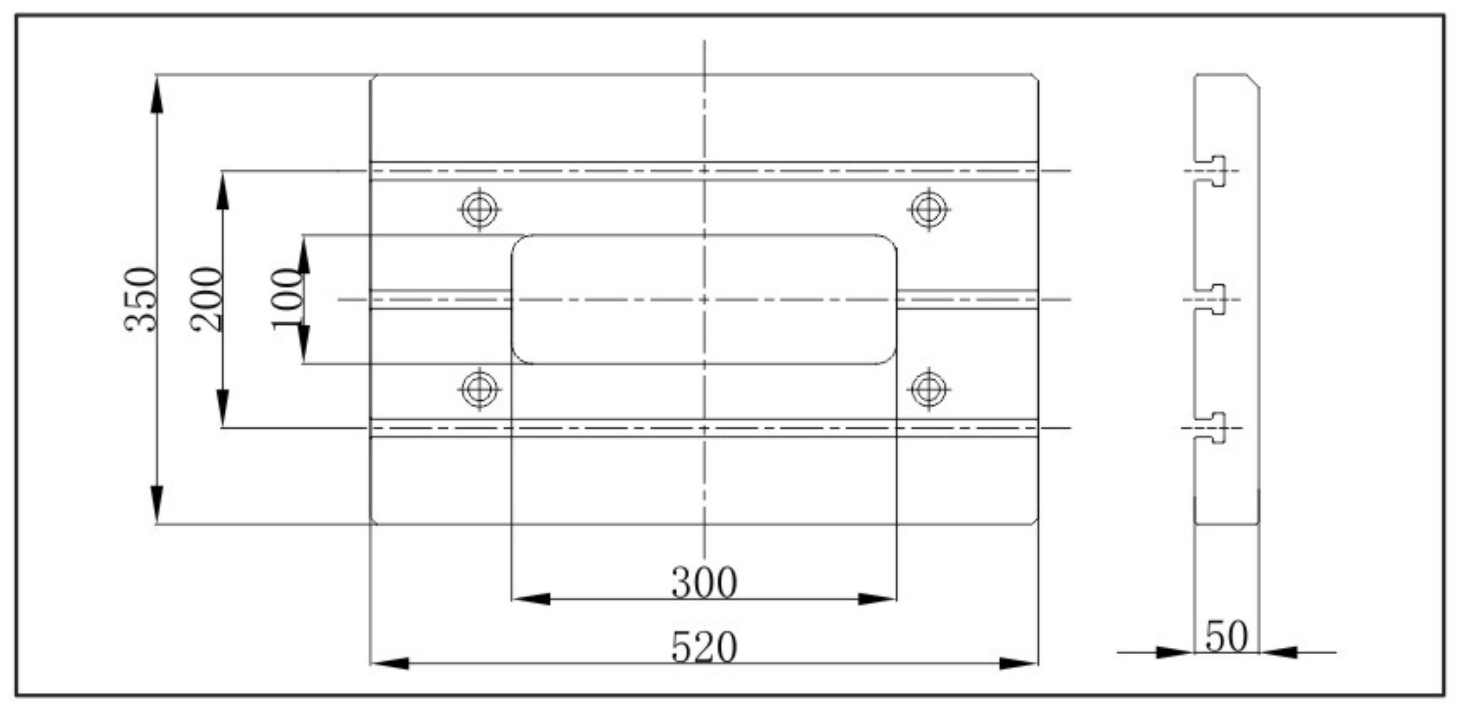

Dimension of lower table mm | 520 x 350 x 45 (L x W x D) | ||

Blanking hole size mm | 300 x 100 | ||

Main motor power | 7.5KW servo | ||

Slide adjustment | 30mm | ||

Working air pressure kg / cm² | 5 | ||

Operation method | Two-hand operation | ||

Press color | Standard off-white | ||

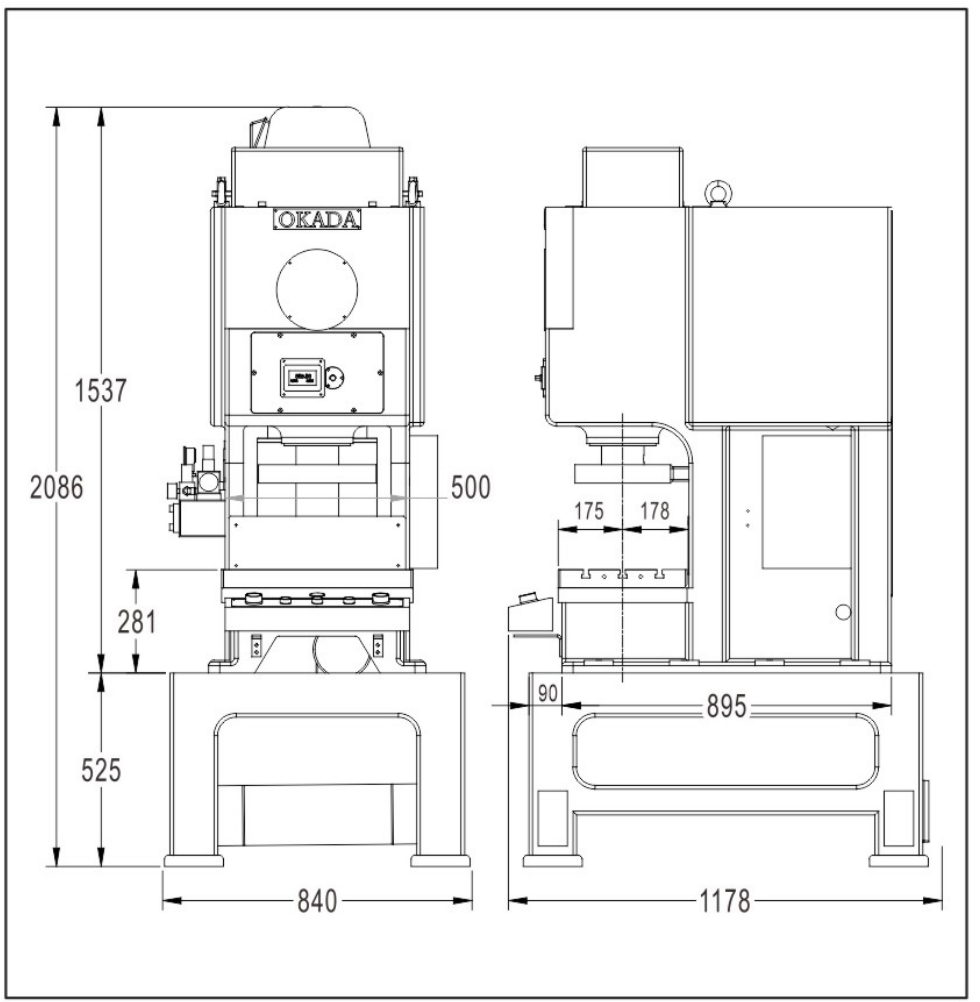

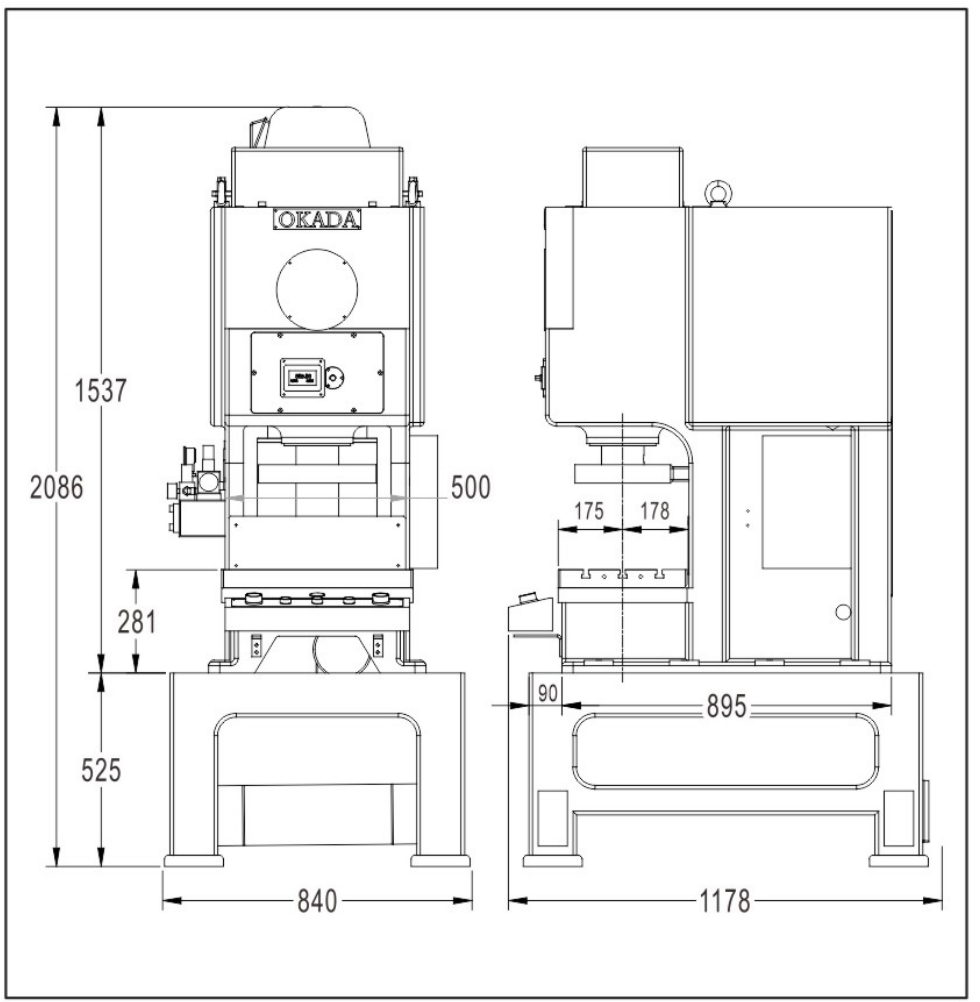

Fuselage mm (L x W x H) | 1178 x 840 x 2086 | ||

Press weight | 1900kg | ||

Specification parameters

Upper workbench

Lower workbench

Dimensions

Product features

1.The machine adopts high strength cast iron to eliminate internal stress,ensure high precision and strong bearing capacity.

2.Pneumatic clutch brake system and high-end solenoid valve ensure safety and stability.

3.The forced circulating lubricating oil device ensures the accuracy and stability of the high-speed operation of the machine,improves the service life of the machine,and is designed with advanced humanization.Electronic monitoring system can improve efficiency and quality.

Configuration

Standard accessory configuration | |

Human-Machine Interface | 1group |

servo motor | 1group |

Programmable logic controller(PLC) | 1group |

Electronic cam structure | 1group |

Inverter control | 1group |

Manual mold height adjustment | 1group |

Standard accessory configuration | |

Circulating lubrication oil supply system | 1group |

Maintenance tools and toolboxes | 1group |

Operating instructions and precision Inspection grade sheet | 1group |

Photoelectric protection configuration | 1group |

Oil pressure locking system | 1group |

Specification parameters

Project Model | SF-20E | ||

Nominal force | 20T | ||

Trip | 20 | 30 | 40 |

Number of trips | 60 ~ 150 | 60 ~ 150 | 60 ~ 120 |

Maximum mold height mm | 190 ~ 220 | 185 ~ 215 | 180 ~ 210 |

Size of upper table mm | 320 x 260 | ||

Installation hole distance of upper table mould | 210–230 | ||

Dimension of lower table mm | 520 x 350 x 45 (L x W x D) | ||

Blanking hole size mm | 300 x 100 | ||

Main motor power | 7.5KW servo | ||

Slide adjustment | 30mm | ||

Working air pressure kg / cm² | 5 | ||

Operation method | Two-hand operation | ||

Press color | Standard off-white | ||

Fuselage mm (L x W x H) | 1178 x 840 x 2086 | ||

Press weight | 1900kg | ||

Specification parameters

Upper workbench

Lower workbench

Dimensions