1.Advanced imported manufacturing technology

2.Humanized appearance design

3.Simple operation man machine interface digital system

4.Perfect combination of efficient production capacity and automatic production line

Standard accessory configuration | |

Human-Machine Interface | 1group |

servo motor | 1group |

Programmable logic controller(PLC) | 1group |

Electronic cam structure | 1group |

Inverter control | 1group |

Manual mold height adjustment | 1group |

Standard accessory configuration | |

Circulating lubrication oil supply system | 1group |

Air source receptacle | 1group |

Maintenance tools and toolboxes | 1group |

Operating instructions and precision Inspection grade sheet | 1group |

Photoelectric protection configuration | 1group |

Oil pressure locking system | 1group |

Specification parameters

Project Model | SF-5 | |||

Nominal force | 5T | |||

Trip | 20 | 30 | 40 | 50 |

Number of trips | 60 ~ 300 | 60 ~ 200 | 60 ~ 100 | 60 ~ 100 |

Maximum mold height mm | 160 ~ 190 | 155 ~ 185 | 150 ~ 180 | 145 ~ 175 |

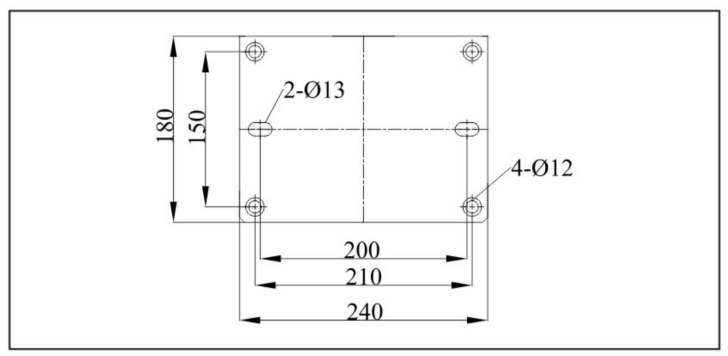

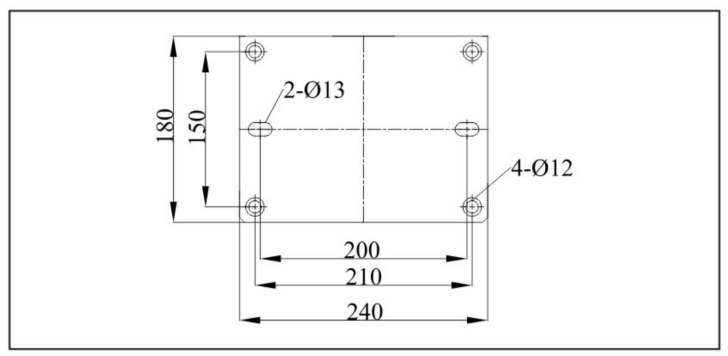

Size of upper table mm | 240x180 | |||

Installation hole distance of upper table mould | 200 | |||

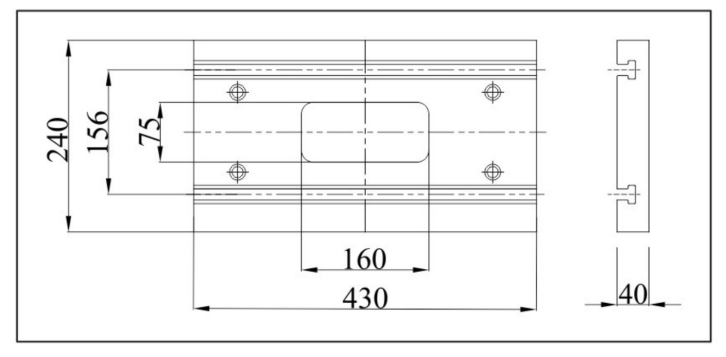

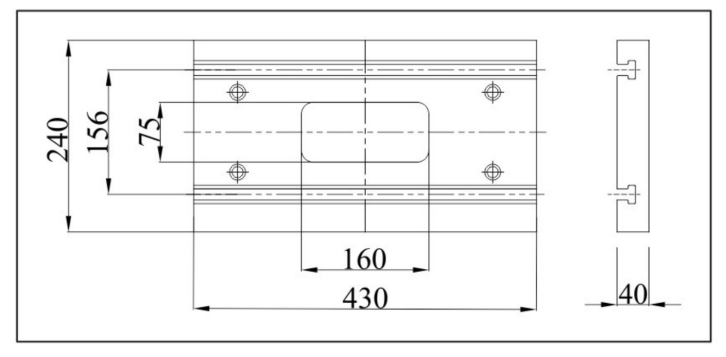

Dimension of lower table mm | 430x240x40 (L x W x D) | |||

Blanking hole size mm | 160x75 | |||

Main motor power | 2.9 | |||

Slide adjustment | 30mm | |||

Mold installation mode | Mould Hanging Method | |||

Working air pressure kg / cm² | 5 | |||

Operation method | Two-hand Operation | |||

Press color | Standard Off-white | |||

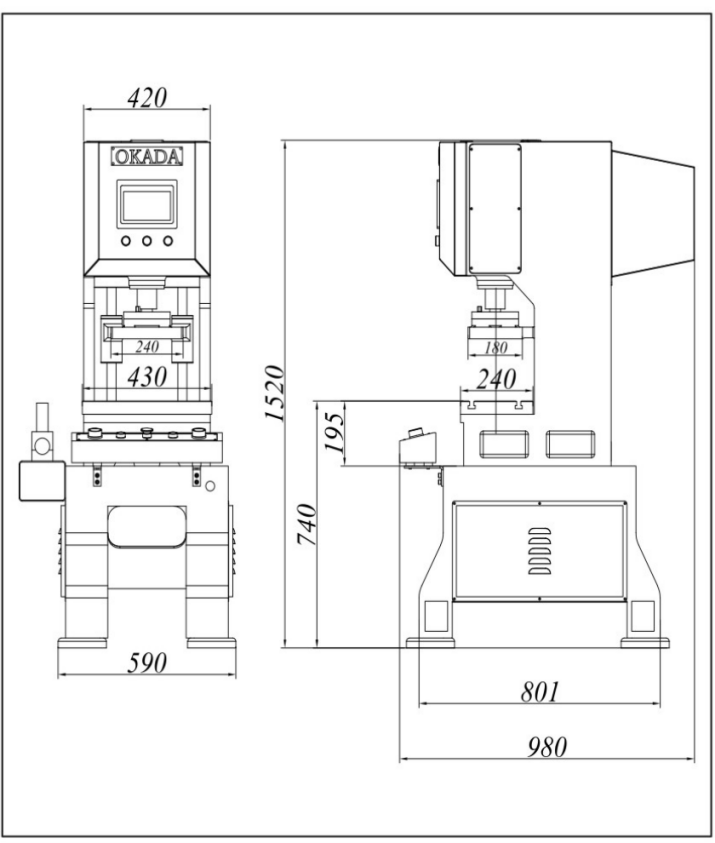

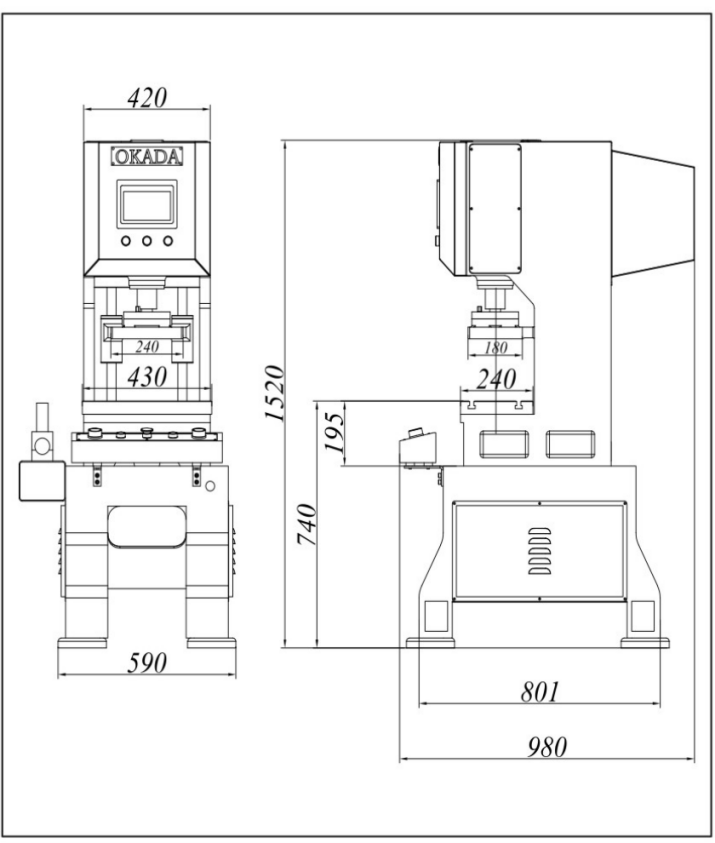

Fuselage mm (L x W x H) | 980x590x1520 | |||

Specification parameters

Upper workbench

Lower workbench

Dimensions

1.Advanced imported manufacturing technology

2.Humanized appearance design

3.Simple operation man machine interface digital system

4.Perfect combination of efficient production capacity and automatic production line

Standard accessory configuration | |

Human-Machine Interface | 1group |

servo motor | 1group |

Programmable logic controller(PLC) | 1group |

Electronic cam structure | 1group |

Inverter control | 1group |

Manual mold height adjustment | 1group |

Standard accessory configuration | |

Circulating lubrication oil supply system | 1group |

Air source receptacle | 1group |

Maintenance tools and toolboxes | 1group |

Operating instructions and precision Inspection grade sheet | 1group |

Photoelectric protection configuration | 1group |

Oil pressure locking system | 1group |

Specification parameters

Project Model | SF-5 | |||

Nominal force | 5T | |||

Trip | 20 | 30 | 40 | 50 |

Number of trips | 60 ~ 300 | 60 ~ 200 | 60 ~ 100 | 60 ~ 100 |

Maximum mold height mm | 160 ~ 190 | 155 ~ 185 | 150 ~ 180 | 145 ~ 175 |

Size of upper table mm | 240x180 | |||

Installation hole distance of upper table mould | 200 | |||

Dimension of lower table mm | 430x240x40 (L x W x D) | |||

Blanking hole size mm | 160x75 | |||

Main motor power | 2.9 | |||

Slide adjustment | 30mm | |||

Mold installation mode | Mould Hanging Method | |||

Working air pressure kg / cm² | 5 | |||

Operation method | Two-hand Operation | |||

Press color | Standard Off-white | |||

Fuselage mm (L x W x H) | 980x590x1520 | |||

Specification parameters

Upper workbench

Lower workbench

Dimensions